Application and parameters of Vat Blue 5

Vat Blue 5

- TRADE NAME:

- Bromo indigo blue

- Bromo Indigo

- Indigo Blue 4B

- Bromo Indigo 2B

CAS NO: 2475-31-2

CI.NO: 73065

Vat Blue 5 Physical and Chemical properties

|

Dyeing depth g/L |

30 |

|

Dyeing method |

IN |

|

Leuco color |

Blue |

|

Leveling property |

▲▲ |

|

Dead cotton |

△ |

|

Light (Xenon test 1/12) |

6-7 |

|

Light (Xenon test 1/1) |

7-8 |

|

Light (Xenon test 2/1) |

7-8 |

Application Features

|

Dyeing method |

Dyeing temperature(℃) |

Reduction Method |

Reduction temperature (℃) |

Leveling Property |

Other properties |

|

most suiable for special method ,also can be used B |

50~60 |

Dry Cylinder |

60~80 |

Good |

Not resistant to alkali cooking |

Colour Fastness Test

|

Light fastness |

Soapping(95℃) |

Perspiration |

Rubbing |

Ironing |

Bleaching resistant |

Mercerized |

|||||||

|

standard depth |

1/12 depth |

orginal color changed |

white fabric stained |

orginal color changed |

white fabric stained |

dry |

wet |

immediately |

4hafter |

Chlorine bleaching |

oxygen bleaching |

orginal color changed |

white fabric stained |

|

4~5 |

— |

4~5 |

5 |

4 |

5 |

5 |

4~5 |

— |

4~5 |

2 |

4 |

4 |

— |

The appearance of Vat Blue 5 (bromo indigo blue) is dark blue powder. It is insoluble in water and alcohol; soluble in xylene, tetrahydronaphthalene, nitrobenzene. It is blue-green in concentrated sulfuric acid, blue after dilution and precipitated. Dye in alkaline powder The leuco body formed in the solution is yellow, and the acid insurance powder solution is pale yellow.

Vat Blue 5 Usage:

1. When bromine indigo is used for cotton product dyeing or dip dyeing, it is most suitable to use special method. It can also be used in B method, but it can be dyed without salt. It needs to be reduced by dry cylinder. The drying time of dry cylinder needs 10~15min, temperature 60~ 80 ° C, dry cylinder stabilization time is more than 60min.

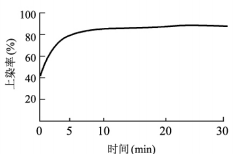

2. The bromine indigo leuco body has higher affinity for cotton fiber and good leveling property. The dyeing curve is shown in Figure 4-5-22. The hiding power of dead cotton is very poor. It should not be washed after dyeing, it should be oxidized in air first. Or put directly into the oxidation bath

Oxidation of (hydrogen peroxide or sodium perborate). After oxidation, it is fully scented by soaping. It is mainly used for cotton yarn dyeing and cotton cloth dyeing, and is generally not used for suspension padding.

3. Bromoindigo is one of the important dyes for vat dyes in cotton printing. It is suitable for direct printing, but also for discharge and anti-dye printing.

Fig4—5—22 Bromo indigo blue staining curve

When the color paste is prepared by the non-pre-reduction method, caustic soda or potassium carbonate is used as the alkali agent, but the color shade is greenish; if the printing paste is prepared by the pre-reduction method, the caustic soda is used as the alkali agent, and heated to 50 ° C, only the white powder is added. Add insurance powder, the color is bright and blue, but the amount of color is not high without pre-reduction method. The printing and dyeing steaming time should not be too long, so as not to affect the normal color development. It is better to use sodium perborate or air to ventilate. When used for printing, in addition to being used as the main color alone, it is often combined with a reduced brown RRD to adjust the color.

4. Bromine indigo is suitable for the dyeing of viscose fiber, and has good leveling property and affinity. It can also be used for the dyeing of cotton blended fabric, but the color of the dye is slightly darker than cotton.

5. The bromine indigo printing and dyeing fabric is finished by BHES resin, and the color light turns green and dark.

Precautions

1. Vat Blue 5 (Bromo indigo blue) is not resistant to alkali cooking and chlorine bleaching, so it can not be used for color fabrics that require alkali boiling and chlorine bleaching. When dry treatment is encountered after printing, the concentration of bleaching liquid should be properly controlled and kept consistent.

2. When bromine indigo is used for large-area printing, the oxidation color must be sufficient. Immediately after oxidation, it should be soaped to prevent the printed fabric from being colored when it is left in a wet state. Soaping should be carried out at 90~95 °C, otherwise When the finished soap is washed, the fading fastness is poor, the green light is heavy and the color is wilted.

3. Vat Blue 5 should be stored in a dry, ventilated place to avoid moisture.

Vat Blue 5 Application:

Mainly used for cotton of jig dyeing and yarn dyeing, dyeing hair blue cloth color turquoise blue. Is the important dye printing, can direct printing, also can discharge printing and resist printing. Can also be used for viscose, silk and wool dyeing, levelness and affinity are good. Can be processed into organic pigment

Packing:

20 or 25kg/compound bag, carton box, iron drum, fiber durm for powder dye and 1000kg/tank for liquid dye

- Inquiry for Vat Blue 5

- Question: *

- You can learn about other products:

- Vat Blue 6

- Vat Orange 11

- Vat Yellow 1

- Vat Yellow 2

- Vat Red 29

- Vat Blue 4

- Vat Blue 1

- Vat Green 8

- Vat Green 3

- Vat Green 1

Products Catalog

- solvent red 24

- solvent red 49

- solvent red 122

- solvent red 111

- solvent red 146

- solvent red 195

- solvent yellow 21

- solvent yellow 33

- solvent yellow 93

- solvent yellow 98

- solvent yellow 114

- solvent orange 60

- vat red 41

- solvent green 3

- solvent green 5

- solvent blue 70

- solvent blue 104

- solvent black 3

- solvent violet 31

- solvent violet 13

Copyright right HANGHZOU EMPEROR CHEMICAL CO,,LTD © 2019 All rights reserved.

Pусский

Pусский